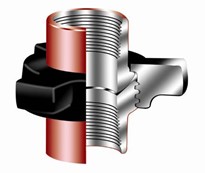

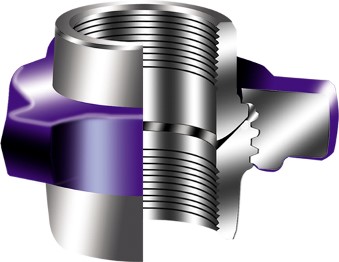

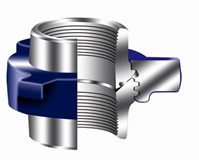

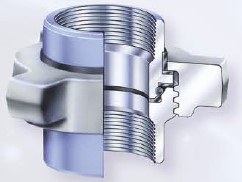

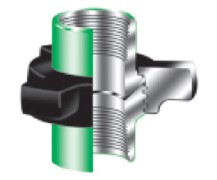

Reliable sealing performance:

Sealing ring adopts imported rubber material for increasing pressure bearing capacity and sealing performance. Seal type depends on pressure and application range.

Quick and easy installation:

Design of wing nut and rigid self-lock type ACME thread can be quick makeup and breakout, no special tools required.

Height interchangeability:

All union structures, connection sizes can be matched with international products, English system size; sealing ring of union can be interchanged with SPM and FMC products. Model and pressure and other markings on wing nut are stamp forged once.

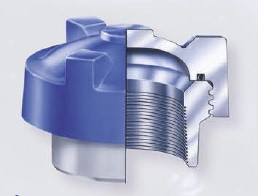

Advanced machining and inspection procedures:

High precision CNC machine can process spherical fitting and special tools can machine LP thread. Wing nuts are machined by CNC machines. Welding material and bevel shall comply with API SPEC 16C specifications; For H2S environment, unions are designed and made as per NACE MR 0175 Stress fracturing material of sulfide resistant for oilfield equipment and API RP-14E specifications.

FIG 100 1000PSI NSCWP, TP1500PSI Black Nut-Yellow--Subs Total Length Nut Radius Material Weight Nut Subs in mm in mm in mm Ibs kgs 2 50.8 3-5/8 92.1 2-15/16 74.6 SF SF 5.25 2.4 2-1/2 63.8 4-1/4 108.0 3-5/8 92.1 SF SF 8.0 3.6 3 76.2 4-15/16 125.4 4-1/16 103.2 SF SF 14.0 6.4 4 101.6 5-15/16 150.8 4-25/32 121.4 SF SF 23.0 10.4 6 152.4 65/8 168.3 6-7/16 163.5 SF SF 44.5 20.2 8 203.2 7-1/4 184.2 7-11/16 195.3 SF SF 61.0 27.7 FIG 200 2000PSI NSCWP, TP3000PSI Blue Nut—Grey Subs Size (inch) Total Length Nut Radius Material Weight Nut Sbs in mm in mm in mm Ibs kgs 1 25.4 2-11/16 68.3 1-15/16 49.2 SC/SF CDB/SF 1.75 0.8 1-1/4 31.7 2-7/8 73.0 2-3/8 60.3 SF SF 2.37 1.1 1-1/2 38.1 2-7/8 73.0 2-3/8 60.3 SF SF 2.37 1.1 2 50.8 3-5/16 84.1 2-29/32 73.8 SF SF 2.25 2.4 2-1/2 63.8 4-1/16 103.2 3-11/16 93.7 SF SF 10.0 4.5 3 76.2 4-13/8 111.1 3-7/8 98.4 SF SF 15.25 6.9 4 101.6 4-13/16 122.2 5 127.0 SF SF 20.0 9.1 6 152.4 6-5/8 168.3 6-7/16 163.5 SF SF 44.5 20.2 8 203.2 7-1/4 184.2 7-11/16 195.3 SF SF 61.0 27.7 FIG 206 2000PSI NSCWP,TP 3000PSI Blue Nut—Grey Subs Size (inch) Total Length Nut Radius Material Size (inch) Nut Subs in mm in mm in mm Ibs kgs 1 25.4 2-11/16 68.3 1-15/16 49.2 SC/SF CDB/SF 1.75 0.8 1-1/2 38.1 2-7/8 73.0 2-3/8 60.3 SF SF 2.37 1.1 2 50.8 3-5/16 84.1 2-29/32 73.8 SF SF 5.25 2.4 2-1/2 63.5 4-1/16 103.2 3-11/16 93.7 SF SF 10.0 4.5 3 76.2 4-3/8 111.1 3-7/8 98.4 SF SF 15.25 6.9 4 101.6 4-13/16 122.2 5 127.0 SF SF 20.0 9.1 6 152.4 6-5/8 168.3 6-7/16 163.5 SF SF 44.5 20.2 8 203.2 7-1/4 184.2 7-11/16 195.3 SF SF 61.0 27.7 FIG 207 2000PSI NSCWP, TP3000PSI Blue Cap—Grey Subs Size (inch) Total Length Nut Radius Material Size (inch) Nut Subs in mm in mm in mm Ibs kgs 3 76.2 3-3/4 95.25 2-7/8 73.03 SC SF 9.8 4.45 4 101.6 4-5/16 109.54 3-19/32 91.28 SC SF 16.25 7.37 6 152.4 5-13/16 147.64 4-31/32 126.2 SC SF 38.0 17.24 FIG 211 2000PSI NSCWP,TP3000PSI Grey Nut—Blue Subs Size (inch) Total Length Nut Radius Material Size (inch) Nut Subs in mm in mm in mm Ibs kgs 2 50.8 3-1/2 88.9 3-1/8 79.38 SF SF 6.25 2.8 3 76.2 4-1/2 114.3 4 101.6 SF SF 12.50 5.7 FIG 300 3000PSI NSCWP, TP4500PSI Black Nut-Green Subs Size (inch) Total Length Nut Radius Material Weight Nut Subs in mm in mm in mm Ibs kgs 1 25.4 2-11/16 68.3 1-15/16 49.2 SC/SF SF 1.75 0.8 2 50.8 3-5/16 84.1 2-29/32 73.8 SF SF 5.25 2.4 Fig 400 4000PSI NSCWP,TP6000PSI Black Nut—Red Subs Size (inch) Total Length Nut Radius Material Total Length Nut Subs in mm in mm in mm Ibs kgs 2 50.8 5-3/16 131.8 3-9/16 90.5 SF SF 11.0 5.0 3 76.2 6-1/4 158.8 4-3/16 106.4 SF SF 19.25 8.7 4 101.8 8-1/8 206.4 5 127.0 SF SF 32.0 14.5 FIG 100

Size (inch)

FIG 200

FIG 206

FIG 207

FIG 211

FIG 300

FIG 400