Flexible multiple high pressure conveying hoses, non-adhesive, no corrosion

Structures of flexible multiple high pressure conveying hoses

The flexible multiple high pressure conveying hose is made of polymer composites. It is a kind of pipes used for petroleum and gas industry. It has the following features: high strength, high pressure, corrosion resistance, scaling resistance, low coefficient of friction resistance, good heat preservation, good flexibility and long service life. The flexible multiple high pressure conveying hose consists of polyethylene resin inner core tube, stainless steel core tube, reinforcement layer and external protection layer.

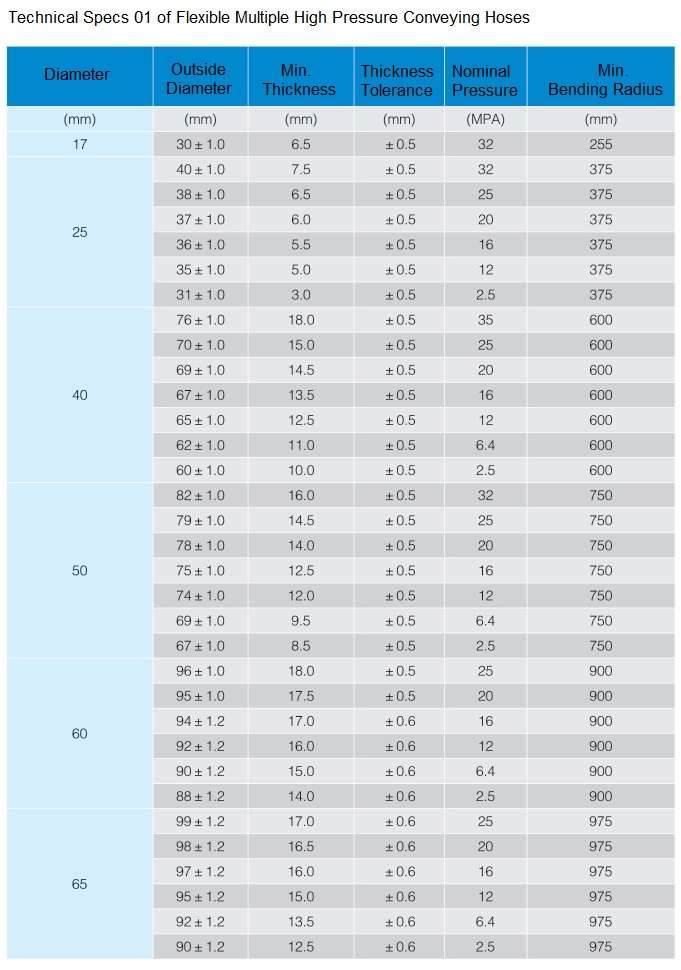

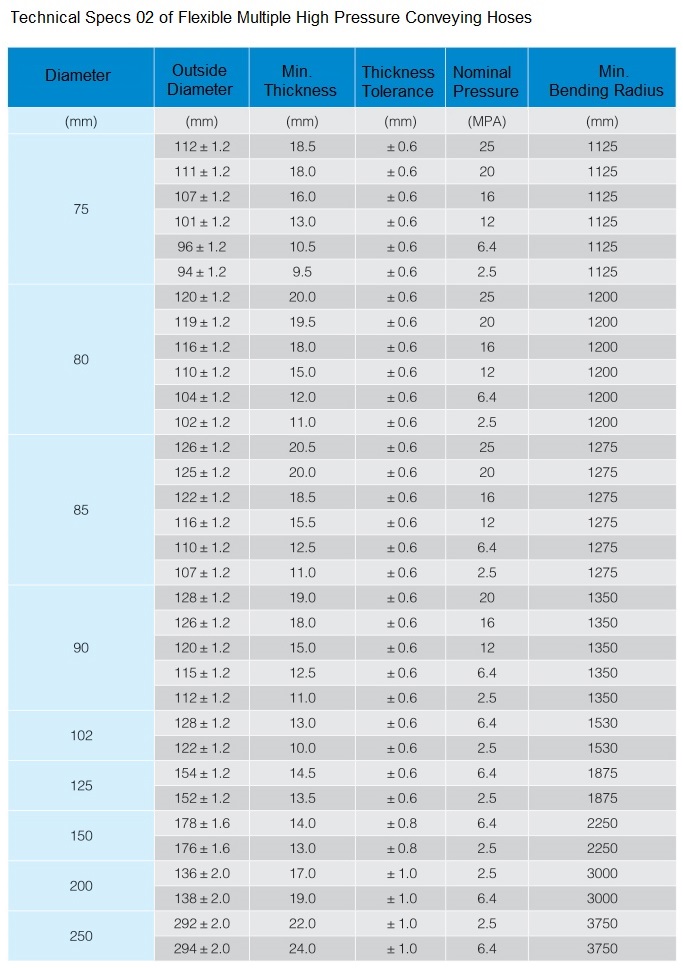

The flexible multiple high pressure conveying hose may divide into oil conveying multiple hose, gas conveying hose, water conveying hose and methanol injection multiple hose according to its use. All kinds of hoses have different diameter, usage, nominal pressure and schedule.

The materials used for making the flexible multiple high pressure conveying hose include stainless steel pipe, polyethylene resin, reinforcement fiber and wireline.

Structures of flexible multiple high pressure conveying hoses

Internal layer

Reinforced layer

Wear-resistant layer

Reinforced layer

External protection layer

Offshore flexible hoses

Application of offshore flexible hoses

Application of offshore flexible hoses includes static and dynamic applications.

Static application: mainly for subsea lines, including oil conveying, gas conveying, water injection and static jumper line

Dynamic application: mainly for connecting floating type production equipment and subsea terminal, or connecting two floating production equipment, including riser and jumper lines.

Jumper line

Jumper line

Riser

Conveying line

Product performances of offshore flexible hoses

Good internal and external pressure resistant performances

Good heat insulation, corrosion and creep resistant performances

Good flexibility, strong subsea suitability, easy and quick installation

Reusable

Design and manufacture as per sea state conditions and mediums

Execution standard: design, production and inspection as per API RP 17B, APRI SPEC 17G, GB/T 20661-2006 standards

Mode of supplying: length as per customer’s requirements.